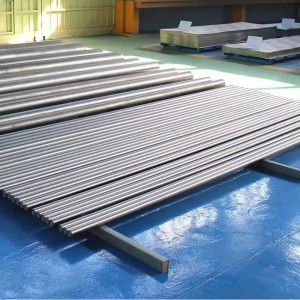

15-7PH/UNS S15700 Plate, Bar, Forging

Available Products

Seamless tube, Plate, Rod, Forgings, Fasteners, Pipe Fittings.

Production Standards

|

Product |

ASTM |

|

Bars, strips and profiles |

A 564, A 484 |

|

Plate, Sheet and Strip |

A 693, A 480 |

|

Forgings |

A 705, A 484 |

Chemical Composition

|

% |

Fe |

Cr |

Ni |

Mo |

C |

Mn |

Si |

P |

S |

Al |

|

Min |

balanced |

14.0 |

6.50 |

2.00 |

|

|

|

|

|

0.75 |

|

Max |

16.0 |

7.75 |

3.00 |

0.09 |

1.00 |

1.00 |

0.040 |

0.030 |

1.50 |

Physical Properties

|

Density |

7.81 g/cm3 |

|

Melting |

1415-1450℃ |

15-7PH Material Properties

15-7PH is a semi-austenitic precipitation hardening stainless steel with high strength, high hardness and good corrosion resistance. The overall corrosion resistance in heat treated TH 1050 and RH 950 conditions is worse than that of standard hardenable stainless steels of the chromium-based 400 series, but not as good as that of the chromium-nickel-based 304 stainless steels.

PH15-7Mo (type 632) national standard 0Cr15Ni7Mo2Al, Japan SUS632, is a steel developed by replacing 2% of chromium in 0Cr17Ni7Al steel with 2% molybdenum. Its basic properties are similar to 0Cr17Ni7Al steel, but the overall performance is better than it. In the austenite state, it can withstand various cold forming and welding processes, and then the highest strength can be obtained after heat treatment; it has excellent high temperature strength below 550 ℃. It is used in the manufacture of aviation thin-walled structural parts, various containers, pipes, springs, valve membranes, ship shafts, compressor discs, reactor parts, and various chemical equipment and other structural parts.

15-7PH Heat Treatment System: A state, TH1050 State, RH950 State, CH900 State Three Heat Treatment Systems

State A: After solution treatment at 1050°C, water cooling or air cooling. The metallographic structure is characterized by austenite.

TH1050 state: After solution treatment at 1050°C, keep at 760°C±15°C for 90min, air-cool, cool to 15°C or room temperature within 1h, keep for 30min, then heat to 565°C±10°C, keep for 90min in air, also known as 565°C aging. The metallographic structure is characterized by precipitation hardening martensite.

RH950 state: After solution treatment at 1050°C, keep at 955°C±15°C for 10 minutes, air-cool to room temperature, cool to -73°C±6°C within 24 hours, keep for 8 hours, then heat to 510°C±6°C, keep for 60 minutes in air-cooling, Also known as 510 ℃ aging. The metallographic structure is characterized by precipitation hardening martensite.

CH900 state: After solution treatment at 1050°C, cold rolling with 60% deformation, heating to 490°C for 60min, air cooling to room temperature. The metallographic structure is characterized by precipitation hardening martensite.

15-7PH Mechanical Properties

(15-7PH) Mechanical properties of 0Cr15Ni7Mo2Al at room temperature

Tensile strength σb (MPa): 565°C aging: ≥1210; 510°C aging: ≥1323;

Conditional yield strength σ0.2 (MPa): 565°C aging: ≥1097.6; 510°C aging: ≥1210;

Elongation δ5 (%): 565°C aging: ≥17; 510°C aging: ≥6;

Reduction of area ψ (%): aging at 565°C: ≥25; aging at 510°C: ≥20;

Hardness HB: State A: ≤269; Aging at 565°C: ≥375; Aging at 510°C: ≥388;

15-7PH Material Application Areas

(15-7PH) 0Cr15Ni7Mo2Al stainless steel is widely used in the chemical industry. It is mainly used to manufacture various containers, pipes, springs, diaphragms, etc. with good corrosion resistance and high strength. Its corrosion resistance exceeds that of martensitic stainless steel, Martensitic precipitation hardening stainless steel and maraging stainless steel.

Diaphragms, welded and brazed honeycomb panels, aircraft diaphragms, springs, retaining rings. Make springs. hot circle. Counter accessories. Medical knives. oil drilling.