Best Quality Hastelloy C-276 Plate - Professional Manufacturer HastelloyC22 / UNS N06022 Tube, Plate, Rod – Guojin

Best Quality Hastelloy C-276 Plate - Professional Manufacturer HastelloyC22 / UNS N06022 Tube, Plate, Rod – Guojin Detail:

Available Products

Seamless tube, Plate, Rod, Forgings, Fasteners, strip, Wire, Pipe Fittings

Chemical Composition

| % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | V | P | S | |

| C22 | min | balance | 20.0 | 12.5 | 2 | 2.5 | |||||||

| max | 22.5 | 14.5 | 6 | 3.5 | 2.5 | 0.015 | 0.5 | 0.08 | 0.35 | 0.02 | 0.02 |

Physical Properties

|

density |

8.9 g/cm3 |

|

Melting |

1325-1370 ℃ |

Minimum mechanical properties of Hastelloy C-22 alloy at room temperature

| Alloy | Rm N/mm2 | RP0.2N/mm2 | A5 % |

| Hastelloy C22 | 690 | 283 | 40 |

Alloy properties

Hastelloy C22 alloy has good resistance to pitting corrosion, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidative aqueous media including wet chlorine, nitric acid or a mixture of oxidative acids containing chloride ions. At the same time, Hastelloy C22 alloy also has ideal resistance to reducing and oxidizing environments encountered in the process. Relying on this versatile performance, it can be used in some troublesome environments, or in a variety of production purpose factories. Hastelloy C22 alloy has exceptional resistance to a variety of chemical environments, including strong oxidizing substances such as ferric chloride, cupric chloride, chlorine, thermally polluted solutions (organic and inorganic), formic acid, acetic acid, acetic anhydride, seawater and salt solution, etc. Hastelloy C22 alloy has the ability to resist the formation of grain boundary precipitation in the welding heat affected zone, which makes it suitable for many chemical process applications in the welded state.

Metallographic structure

Hastelloy C22 has a face-centered cubic lattice structure.

Corrosion resistance

Hastelloy C22 alloy is suitable for various chemical process industries containing oxidizing and reducing media. The higher molybdenum and chromium contents make the alloy resistant to chloride ions, and the tungsten element further improves its corrosion resistance. Hastelloy C22 is one of only a few materials resistant to corrosion in wet chlorine, hypochlorite, and chlorine dioxide solutions. copper chloride).

Application field

Hastelloy C22 alloy is widely used in chemical and petrochemical fields, such as components and catalytic systems in contact with chloride-containing organics. This material is especially suitable for use in high temperature, inorganic and organic acids mixed with impurities (such as formic acid and acetic acid), and seawater corrosive environments.

Other application areas

1. Acetic acid/acetic anhydride

2. Pickling

3. Cellophane manufacturing

4. Chlorination system

5. Complex Mixed Acids

6. Rollers of electro-galvanizing tank

7. Expansion bellows

8. Flue gas cleaning system

9. Geothermal Wells

10. Hydrogen fluoride furnace cleaner

11. Incineration cleaner system

12. Nuclear fuel regeneration

13. Insecticide production

14. Phosphoric acid production

15. Pickling system

16. Plate heat exchanger

17. Selective Filtration System

18. Sulfur dioxide cooling tower

19. Sulfonation system

20. Tube heat exchanger

21. Surfacing valve

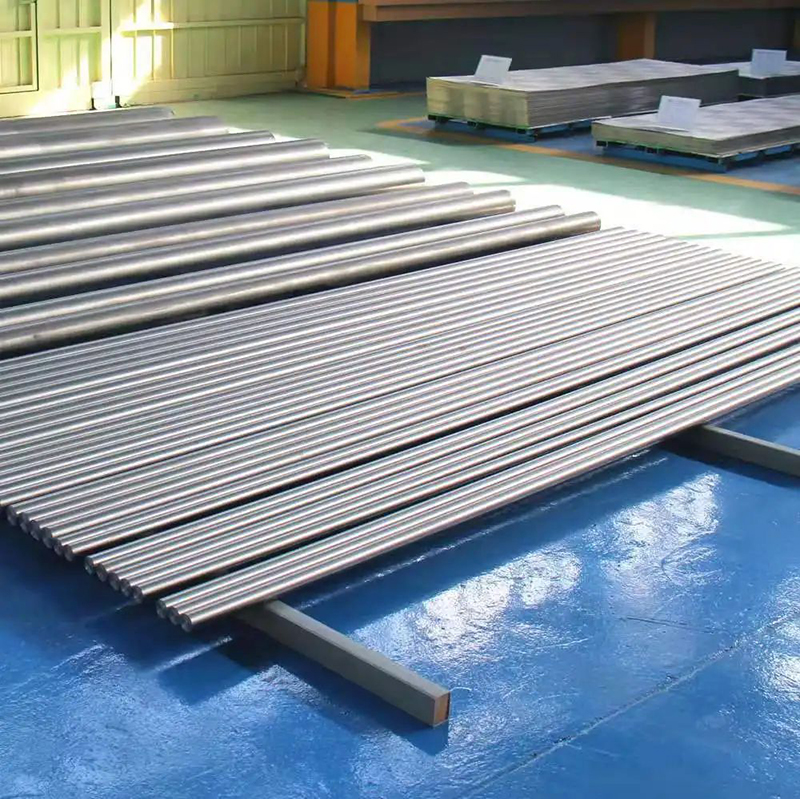

Product detail pictures:

Related Product Guide:

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for Best Quality Hastelloy C-276 Plate - Professional Manufacturer HastelloyC22 / UNS N06022 Tube, Plate, Rod – Guojin , The product will supply to all over the world, such as: Kenya, Swiss, Mexico, Since its foundation , the company keeps living up to the belief of honest selling , best quality , people-orientation and benefits to customers. We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!