Incoloy 800/ UNSN08800/ Alloy800 Seamless Pipe, Sheet, Bar Manufacturer

Available Products

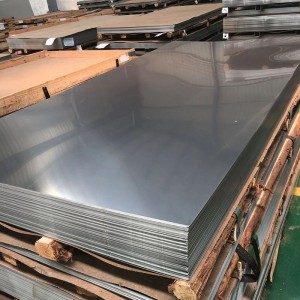

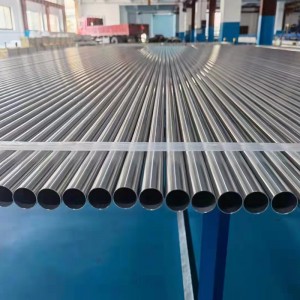

Seamless tube, Plate, Rod, Forgings, Fasteners, Pipe Fittings

Production Standards

| Product | ASTM |

| Bar | B 408 |

| Plate, Sheet and Strip | A 240, A 480, B 409, B 906 |

| Seamless pipes and fittings | B 407, B 829 |

| Welded pipe | B 514, B 775 |

| Welded fittings | B 515, B 751 |

| Solder connection | B 366 |

| Forging | B 564 |

Chemical Composition

|

% |

Fe |

Ni |

Cr |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

Min |

39.5 |

30.0 |

19.0 |

|

|

|

|

|

0.15 |

0.15 |

|

Max |

|

35.0 |

23.0 |

0.10 |

1.50 |

1.00 |

0.015 |

0.75 |

0.60 |

0.60 |

Physical Properties

| Density | 7.94 g/cm3 |

| Melting | 1357-1385℃ |

Incoloy 800 Features

The Cr content in Incoloy 800 alloy is usually 15-25%, the nickel content is 30-45%, and contains small amounts of aluminum and titanium. Incoloy800 alloy is in the austenite single-item region after rapid cooling from high temperature, so the use state is a single austenite structure. The alloy has high chromium content and sufficient nickel content, so it has high high temperature corrosion resistance and is widely used in industry. In chloride, low concentration NaOH aqueous solution and high temperature and high pressure water, it has excellent resistance to stress corrosion cracking, so it is used to manufacture equipment that is resistant to stress corrosion cracking.It has excellent corrosion resistance, good stress corrosion resistance and good processability in extremely high temperature aqueous media up to 500℃.

Incoloy800 Application Areas

Nitric acid condenser - corrosion resistant to nitric acid, steam heating tube - good mechanical properties, heating element tube - good mechanical properties, for applications up to 500°C, the alloy is supplied in the annealed condition.

1.Chemical industry

2.Nuclear generator

3.Nitric acid cooler, acetic anhydride cracking tube

4.Heat exchange equipment, heat exchange tubes