IncoloyA-286/ UNSS66286 High Temperature Nickel Base Alloy Manufacturer

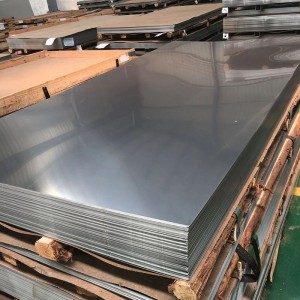

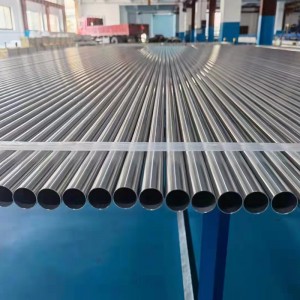

Available Products

Seamless tube, Plate, Rod, Forgings, Fasteners, Pipe Fittings

Production Standards

|

Production standards |

|

|

Product |

ASTM |

|

Forged bar |

A 638, A 484 |

Chemical Composition

|

% |

Fe |

Ni |

Cr |

C |

Si |

Mn |

P |

S |

Ti |

Mo |

V |

Al |

B |

|

Min |

balance |

24.0 |

13.5 |

|

|

|

|

|

1.90 |

1.00 |

0.10 |

|

0.0010 |

|

Max |

27.0 |

16.0 |

0.08 |

1.00 |

2.00 |

0.040 |

0.030 |

2.35 |

1.50 |

0.50 |

0.35 |

0.010 |

Physical Properties

| Density | 7.94g/cm3 |

| Melting | 1370-1430℃ |

Incoloy A-286 Material Properties

IncoloyA-286 nickel-based alloy is Fe-25Ni-15Cr-based superalloy, which is comprehensively strengthened by adding molybdenum, titanium, aluminum, vanadium and trace boron. It has high yield strength, lasting and creep strength below 650℃, and has good processing plasticity and satisfactory welding performance. It is suitable for the manufacture of high-temperature load-bearing parts of aero-engines that work for a long time below 650 °C, such as turbine disks, press disks, rotor blades and fasteners. The alloy can produce deformed products of various shapes, such as discs, forgings, plates, rods, wires and rings. IncoloyA-286 nickel-based alloy improves the purity of the alloy, limits the gas content, controls the content of low melting point elements, and adjusts the heat treatment system, so as to improve the thermal strength and long-term performance of the alloy.

Incoloy A-286 Material Application Areas

Aircraft and industrial gas turbines are subject to high levels of heat and pressure with temperatures up to 700°C in components such as turbine wheels and blades, frames and afterburner components. It is also used in fasteners for car engines.