Inconel600/ Alloy600/ UNS N06600 Tube, Plate, Rod Manufacturer

Available Products

Seamless tube, Plate, Rod, Forgings, Fasteners, Pipe Fittings

Production Standards

|

Product |

ASTM |

|

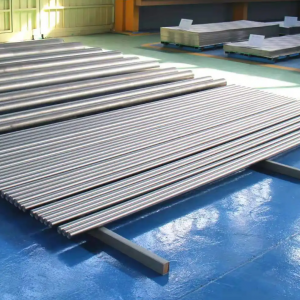

Bar and wire |

B 166 |

|

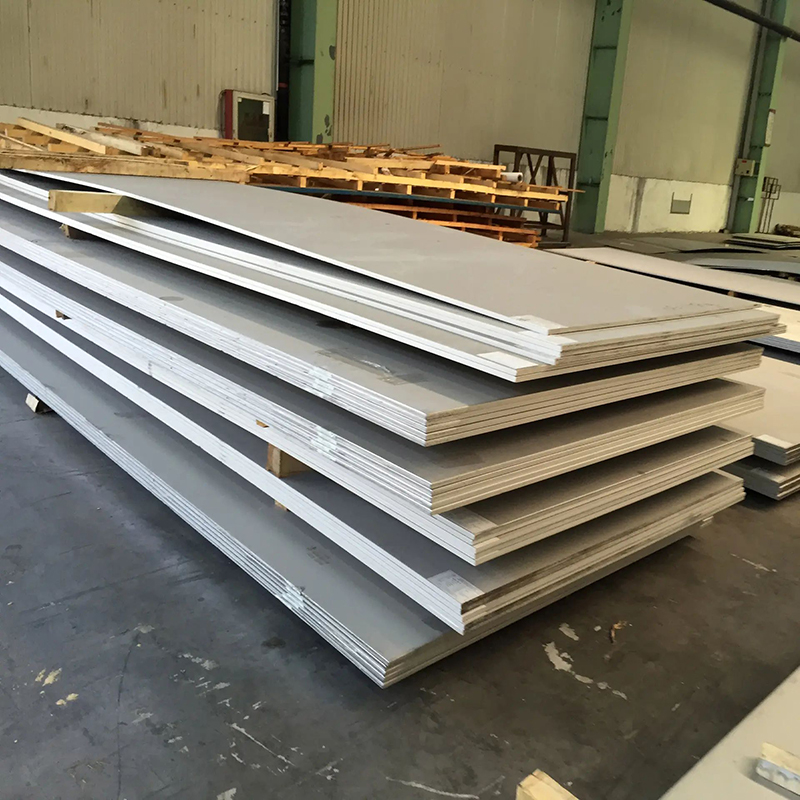

Plate, Sheet and Strip |

B 168, B 906 |

|

Seamless pipe,tube |

B 167, B 829 |

|

Welded pipe |

B 517, B 775 |

|

Weld tube |

B 516, B 751 |

|

Welded pipe fittings |

B 366 |

|

Billets and billets for forging |

B 472 |

|

Forging |

B 564 |

Chemical Composition

|

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

S |

Cu |

|

Min |

72.0 |

14.0 |

6.0 |

|

|

|

|

|

|

Max |

|

17.0 |

10.0 |

0.15 |

1.00 |

0.50 |

0.015 |

0.50 |

Physical Properties

| Density | 8.47 g/cm3 |

| Melting | 1354-1413℃ |

Inconel 600 Features

Inconel600 alloy is a nickel-chromium-iron-based solid solution strengthened alloy with good high temperature corrosion resistance and oxidation resistance, excellent cold and hot processing and welding properties, and has satisfactory thermal strength and high plasticity below 700 ℃.

Inconel 600 is both corrosion and high temperature resistant, strong and easy to machine. Resists chloride stress corrosion cracking, sulfide and oxidizing media in high temperature environments. It has good corrosion resistance in organic acids such as formic acid, acetic acid and stearic acid, and has moderate corrosion resistance in inorganic acids. Excellent corrosion resistance in high-purity water used in the primary and secondary cycles of nuclear reactors. Particularly outstanding performance is the ability to resist the corrosion of dry chlorine and hydrogen chloride, and the operating temperature is up to 650 ℃. At elevated temperatures, Inconel 600 in the annealed and solution treated condition has good resistance to oxidation spalling and high strength in air.

Inconel 600 Similar Grades

GH3600, GH600 (China), NC15Fe (France), W. Nr .2.4816, NiCr15Fe (Germany), NA14 (UK) Inconel600, UNS NO6600 (USA) NiCr15Fe8 (ISO) Inconel600 Executive Standard: UNS N06600, DIN/EN 2.4816, ASTM B168, ASME SB-168, AMS 5540, NCF 600

Application

Heat treatment furnaces, aircraft fuselage components, chemical production in nuclear reactors, stills and components.

● Thermowells in aggressive atmospheres

● Vinyl chloride monomer production: resistance to chlorine, hydrogen chloride, oxidation and carbonization corrosion

Oxidative conversion of uranium to hexafluoride: resistant to hydrogen fluoride corrosion

Fields of production and use of corrosive alkali metals, especially environments where sulfides are used

● Preparation of titanium dioxide by chlorine method

● Production of organic or inorganic chlorides and fluorides: resistant to chlorine and fluorine corrosion

● Nuclear reactor

Retorts and components in heat treatment furnaces, especially in carbonizing and nitriding atmospheres

● Alloy 600H is recommended for catalytic regenerators in petrochemical production in applications above 700°C for longer service life.