Manufacturer HastelloyC4/UNS N06455 Tube,Plate,Rod

Available Products

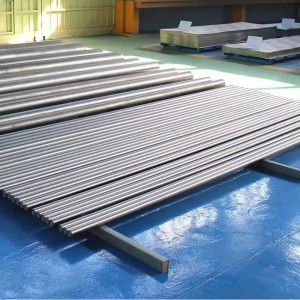

Seamless tube, Plate, Rod, Forgings, Fasteners, strip, Wire, Pipe Fittings

Chemical Composition

|

% |

Ni |

Cr |

Mo |

Fe |

Ti |

Co |

C |

Mn |

Si |

P |

S |

V |

|

Min |

Balance |

14.0 |

14.0 |

|||||||||

|

Max |

18.0 |

17.0 |

3.0 |

0.7 |

2.0 |

0.015 |

0.50 |

0.08 |

0.040 |

0.030 |

0.35 |

Physical Properties

|

Density |

8.64 g/cm3 |

|

Melting |

1350-1400℃ |

Hastelloy C-4 is an austenitic low carbon nickel-molybdenum-chromium alloy. The main difference between Hastelloy C-4 and other earlier developed alloys of similar chemical composition is the low carbon, silicon, iron, and tungsten content. Such a chemical composition enables it to exhibit excellent stability at 650-1040°C, improves resistance to intergranular corrosion, and can avoid edge-line corrosion susceptibility and weld heat-affected zone corrosion under appropriate manufacturing conditions.

Material Properties

●Excellent corrosion resistance to most corrosive media, especially in reduced state.

●Excellent localized corrosion resistance among halides.

Application field

It has been widely used in most chemical fields and high temperature environments. Typical application areas:

●Flue gas desulfurization system

●Pickling and acid regeneration plant

●Acetic acid and agrochemical production

●Titanium dioxide production (chlorine method)

●Electrolytic plating

Welding Performance

Hastelloy C-4 can be welded by various welding processes, such as tungsten electrode inert gas shielded welding, plasma arc welding, manual sub-arc welding, metal shielded inert gas welding, and molten inert gas shielded welding. Pulse arc welding is preferred.

Before welding, the material should be in annealed state to remove oxide scale, oil stains and various marking marks, and the width of about 25mm on both sides of the weld should be polished to a bright metal surface.

With low heat input, the interlayer temperature does not exceed 150°C.